The only function of an OCPD that matters when it comes to an arc flash, is the instantaneous setting and how fast can a breaker open the circuit and stop the current flow to the fault.

“Normal Operations” which is Pandora’s box when it comes to people being safe and wearing the proper PPE. So many folks and yes even “experts” in the field are getting this all wrong so we intend to open Pandora’s box starting Today!!

Let’s start with some basic items that we know about the 70E; 1.) the definition of a qualified worker is…. Qualified Person. One who has demonstrated skills and knowledge related to the construction and operation of electrical equipment and installations and has received safety training to identify and avoid the hazards involved. 2.) One must read the actual wording of the 70E (carefully and completely) and what’s not written is at times just as important.

All the follow information precedes table 130.7 and must be analyzed before we can even start to discuss this.

130.2

(A) Energized Work.

(1) Additional Hazards or Increased Risk. Energized work shall be permitted where the employer can demonstrate that de-energizing introduces additional hazards or increased risk. Easy to say but just give an example, go on try! I worked in the field for 30 years and used only one energized work permit where power might have been lost to an entire district, large city or super critical equipment. Believe me, coming up with a good justified reason is much harder than you think.

(2) Infeasibility. Energized work shall be permitted where the employer can demonstrate that the task to be performed is infeasible in a de-energized state due to equipment design or operational limitations. Make sure it’s not just convenient but it really is a hazard.

(3) Less Than 50 Volts. Energized electrical conductors and circuit parts that operate at less than 50 volts shall not be required to be de-energized where the capacity of the source and any overcurrent protection between the energy source and the worker are considered and it is determined that there will be no increased exposure to electrical burns or to explosion due to electric arcs.

Informational Note No. 1: Examples of additional hazards or increased risk include, but are not limited to, interruption of life-support equipment, deactivation of emergency alarm systems, and shutdown of hazardous location ventilation equipment.

Informational Note No. 2: Examples of work that might be performed within the limited approach boundary of exposed energized electrical conductors or circuit parts because of infeasibility due to equipment design or operational limitations include performing diagnostics and testing (for example, start-up or troubleshooting) of electric circuits that can only be performed with the circuit energized and work on circuits that form an integral part of a continuous process that would otherwise need to be completely shut down in order to permit work on one circuit or piece of equipment.

(4) Normal Operation. Normal operation of electric equipment shall be permitted where all of the following conditions are satisfied: I will address each one of these following.

(1) The equipment is properly installed.

(2) The equipment is properly maintained.

(3) The equipment doors are closed and secured.

(4) All equipment covers are in place and secured.

(5) There is no evidence of impending failure.

Informational Note: The phrase properly installed means that the equipment is installed in accordance with applicable industry codes and standards and the manufacturer’s recommendations. The phrase properly maintained means

that the equipment has been maintained in accordance with the manufacturer’s recommendations and applicable industry codes and standards.

The phrase evidence of impending failure means that there is evidence such as arcing, overheating, loose or bound equipment parts, visible damage, or deterioration. How can you tell or witness this and not open the door exposing live parts, high resistance connections cannot be seen, only felt or detected if enough heat is given off or you have an infra-red camera looking at the switchgear, but again you must open the door to check and that requires the PPE for the job?

(B) Energized Electrical Work Permit.

(1) When Required. When energized work is permitted in accordance with 130.2(A), an energized electrical work permit shall be required under the following conditions:

(1) When work is performed within the restricted approach boundary

(2) When the employee interacts with the equipment when conductors or circuit parts are not exposed but an increased likelihood of injury from an exposure to an arc flash hazard exists

(2) Elements of Work Permit. The energized electrical work permit shall include, but not be limited to, the following items:

- Description of the circuit and equipment to be worked

- on and their location

- Justification for why the work must be performed in an

- energized condition [see 130.2(A)]

- Description of the safe work practices to be employed

- (see 130.3)

- Results of the shock risk assessment [see 130.4(A)]

- Voltage to which personnel will be exposed

- Limited approach boundary [see 130.4(B), Table

- 4(D)(a), and Table 130.4(D)(b)]

- Restricted approach boundary [see 130.4(B) and

Table 130.4(D)(a) and Table 130.4(D)(b)]

130.2 ARTICLE 130— WORK INVOLVING ELECTRICAL HAZARDS

70E–24 ELECTRICAL SAFETY IN THE WORKPLACE 2015 Edition

Informational Note No. 1: The arc flash PPE category, work tasks, and protective equipment provided in Table

130.7(C)(15)(A)(a), Table 130.7(C)(15)(A)(b), and Table

130.7(C)(15)(B) were identified and selected, based on the collective experience of the NFPA 70E Technical Committee.

Here is what the committee said which proves beyond a doubt that only qualified, experienced electricians be involved and stay alert to the dangers. Please read all of it!

The arc flash PPE category of the protective clothing and equipment is generally based on determination of the estimated exposure level.

Informational Note No. 2: The collective experience of the NFPA 70E Technical Committee is that, in most cases, closed doors do not provide enough protection to eliminate the need for PPE in situations in which the state of the

equipment is known to readily change (e.g., doors open or closed, rack in or rack out).

Informational Note No. 3: The premise used by the NFPA 70E Technical Committee in developing the criteria discussed in Informational Note No. 1 and Informational

Note No. 2 is considered to be reasonable, based on the consensus judgment of the committee.

Informational Note No. 1: “Short-circuit current,” as used in this table, is determined from the dc power system maximum available short-circuit, including the effects of cables and any other impedances in the circuit. Power system modeling is the best method to determine the available short-circuit current at the point of the arc. Battery cell short-circuit current can be obtained from the battery manufacturer. See Informative Annex D.5 for the basis for table values and alternative methods to determine dc incident energy. Methods should be used with good engineering judgment.

Informational Note No. 2: The methods for estimating the dc arc flash incident energy that were used to determine the categories for this table are based on open-air incident energy calculations. Open-air calculations were used because many battery systems and other dc process systems are in open areas or rooms. If the specific task is within in an enclosure, it would be prudent to consider additional PPE protection beyond the value shown in this table. Research with ac arc flash has shown a multiplier of as much as 3x for arc-in-a-box [508 mm (20 in.) cube] versus open air.

Engineering judgment is required when reviewing the specific conditions of the equipment and task to be performed, including the dimensions of the enclosure and the working distance involved.

Wow, now that’s a lot to think about, just reading what the committee wanted us to be informed of to ????? determine whether or not we should wear proper PPE and take precautions required???? And here is the table that says, “Normal Operation” only when ALL conditions are meet can you even think about wearing less PPE than Normal. Are you confused yet?

Table 130.7(C)(15)(A)(a) Arc Flash Hazard Identification for Alternating Current (ac) and Direct Current (dc) Systems

Task Equipment Condition*

Is Arc Flash PPE Required ? Yes or No

Reading a panel meter while operating a meter switch NO

Normal operation of a circuit breaker (CB), switch, contactor, or starter

If All of the following: NO

- The equipment is properly installed

- The equipment is properly maintained

- All equipment doors are closed and secured

- All equipment covers are in place and secured

- There is no evidence of impending failure

IF one or more of the following: YES

- The equipment is not properly installed

- The equipment is not properly maintained

- Equipment doors are open or not secured

- Equipment covers are off or not secured

- There is evidence of impending failure

For ac systems: Work on energized electrical conductors and circuit parts, including voltage testing YES

The equipment is properly installed. How do you know this? Do you have documents showing that the equipment was professionally installed and then checked by independent inspection specialist trained in NEC code for switchgear installation? Has anyone changed anything since it was installed and has any maintenance been done?

The equipment is properly maintained. Do you have the proper records from testing and maintenance companies who performed tests on the equipment to ensure the safe reliable operation of the equipment and was it done in accordance with NETA (National Electrical Testing Association)?

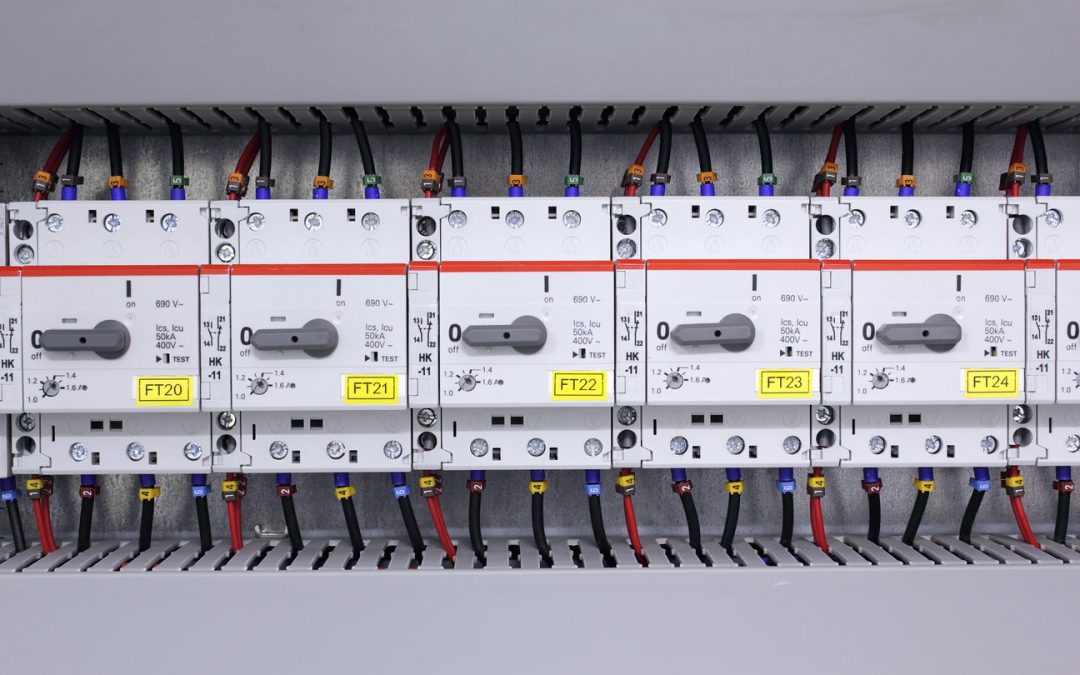

All equipment doors are closed and secured. When it says doors closed and secured they mean that all bolts and fasteners that were supplied with the equipment are still being used and are in good shape, properly installed and tightened down.

All equipment covers are in place and secured. Same precautions, do you have all the covers or are some missing with live circuit parts exposed?

There is no evidence of impending failure. Again, how can you know this without opening the door or taking covers off to determine if such conditions are present and some serious problems can lie hidden until the equipment is operated such as in non-functional interlocks and /or loose connections that can get much worse to the point of causing arcing on the switchgear current carrying conductors and bus ways.

My business for 10 years in Washington State, was a testing/maintenance business in which we would test and verify all of the items above but until a customer hired us to do so, they had no idea of the condition of their equipment and could never say any of the items above were actual. Long before the NFPA 70E was written and these items were of the 70E concern, the NETA association members and certification process helped us in determining the condition of the equipment and its continued serviceability so most of this has been around for many years and is well documented by NETA. The folks associated with this type of work did so every day and know the tasks are difficult and often, items were missed due to the nature and accessibility of the equipment for detailed inspections. It is my opinion and that of my partner at ILS, we will always wear the proper PPE no matter what. I hope you will draw the same conclusion and realize the danger is always present, just hidden at times. Don’t let it jump out and bite you!!!!!!!

Much more to come but this gets us started in opening Pandora, and please send us your comments to Dan and/or myself thru our web site or call me if you would like to debate this more. Next week I promise to have more items that Pandora is hiding.