I cannot express my concerns enough when it comes to this subject and I must clear up some misconceptions that, (sad to say), experienced electrical people, engineers, supervisors, and anyone who has ever been a part of this have been told, taught, and performed some of the most dangerous steps I have witnessed, Including ME!

How many of you have heard someone say, “just stab the bus, it will all be over in a second”? Sure, it’s dead, go ahead and ground it! And similar such phrases that can and will get you killed. I was once instructed to slap the bus with my grounding cable and, I was issued by my employer (one of the top 3 electrical companies at that time) ordinary jumper cables 6 awg (cables used to jump your car with clips for connecting to the battery) for personal protective grounds. This was an acceptable practice at the time?

- Never stab any bus! You cannot complete that even if you think you can, electricity is much faster than you. It will jump the air gap when close enough and you will be blown back by a tremendous force, much more than you can imagine. You are not fast enough, big enough, or strong enough to accomplish such a ridiculous task.

- Using number 6 awg cables with clips, would result in another explosion, the 20k to 30k fault current will instantly destroy the cables and you can bet that you can do nothing to stop it! Look up the maximum ampacity that a number 6 awg cable can handle for 10 cycles. Just for an example and comparison, a number 2/0 awg cable can handle 20K amps or 15 cycles before it is destroyed and that size of cable might work!

Now with that said, what can we do safely to ensure the equipment is de-energized and grounded as required by the NFPA 70E (above 1000volts)? I mentioned in my last blog that maybe we need to use technology in the dangerous lines of work we perform such as; the use of remote controls to open and close circuit breakers; use of grounding devices that can be manufactured to be safe for us operate, designed systems that prevent accidental energization and making it impossible to gain access to the live bus unless the bus is dead (electrically sensing) and grounded by mechanical means.

I am very pleased to see this type of equipment is being installed all over the country. We need to do more however and with a tremendous amount of our electrical distribution equipment is in dire need of replacement (50 to 60 years old) Now is the time to limit human interaction with live circuits thru design.

Let me now tie in the metering blogs with the grounding discussions and the NFPA 70E required measurements for zero energy, (using full contact metering and non-contact detectors) phase to phase and phase to ground.

Let’s use 12.47kV medium voltage, wye connected system for our discussion.

Points:

- Phase to Phase 12.47kV

- Phase to Ground 7.2kV

How will we prove that the systems are de-energized using full contact instruments/meters? Must be rated for 20kV, PPE such as flash suits (need cal/cm2 to be able to select correct protection level), 20kV rated gloves, insulating sticks to help reach the bus or breaker stabs inside a breaker cell, (reminds me of a metal coffin)?

Would it be nice if we had an installed meter on the switchgear that we could use for this? Why is it necessary for me or you to climb inside a breakers cell and make a full contact measurement?

Would it be nice if we had an installed meter on the switchgear that we could use for this? Why is it necessary for me or you to climb inside a breakers cell and make a full contact measurement?

What if I use the non-contact 122kV rated detector on a 6ft hot stick, that tells me If anything is energized? How do I satisfy the Phase to Phase, Phase to Ground measurements? As are required in the NFPA 70E.

So how can we make sure the bus is dead and apply grounds for our protection? Which method is acceptable? Does the NFPA 70E suggest that we suit up and risk our lives?

Please remember, The NFPA 70E is a guide to help you make wise, informed decisions concerning your safety. SO, we need to plan the job and make decisions on how we are going to accomplish the tasks safely.

A decision must be made and mine would be to have a smart meter installed (if not already) and use that meter to determine Zero/energy. The non-contact detector can be used as an additional way of ensuring the power is off, indicating lights, and other items that change state when energized/de-energized can also be observed.

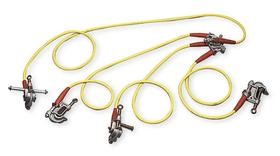

Have all the information I would need for Cal/Cm2, fault currents, cable sizing and type of clamps needed for positive connection to the bus bars. At one plant, we installed grounding ball clamps (trailer hitch style) on the bus and had cables made to fit the grounding ball connector. It was a very good/safe way of grounding the bus after we performed the required Zero energy check.

Examples of approved grounding sets for specific types of electrical gear.

Examples of approved grounding sets for specific types of electrical gear.

This is a grounding breaker in which I will explain on my next blog, but for now just bringing other thoughts and procedures that could be implemented.

I hope this blog gives you some ideas and perhaps a different way of solving this critical/dangerous task of Zero energy testing and grounding in a safe manor.

See you next week